What is the application of the rational moulding process?

Plastics Rotomolding, occasionally known as roto-moulding, rotatable casting, and in many cases redraft, is actually a plastics recycling approach that creates very durable things with virtually limitless lifespans. Several options are around for causal versions, with polypropylene (PE) grades being probably the most moulded materials.

– The roto-moulding approach necessitates utilizing a mould or instrument, which may be made by different operations such as fabrication, casting, or machining.Rotational Molding, at times known as roto-moulding, rotatable throwing, and in many cases redraft, is actually a plastics trying to recycle approach that produces very durable goods with virtually limitless lifespans.

– A variety of places are around for causal versions, with polypropylene (PE) levels getting by far the most typically moulded fabric.

What exactly is the process of realistic moulding?

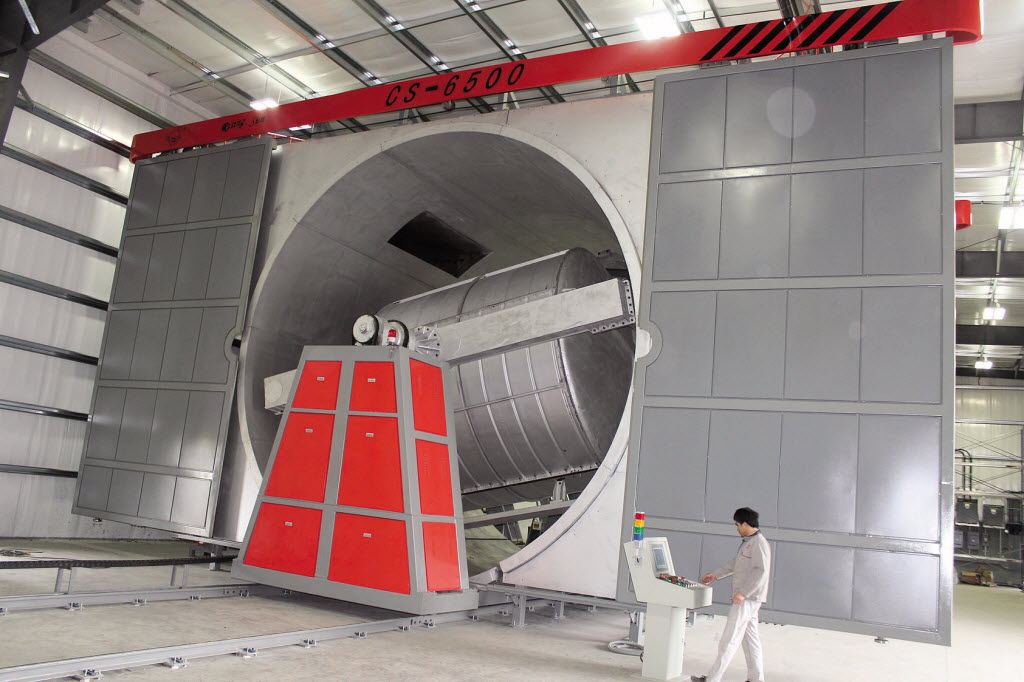

Rotational moulding is actually a easy thought. A powdered plastic-type substance is put in to a hollow mould, usually built of cast aluminium or produced from sheet metallic. The form is closed and progressively rotated on two axes. The polymer progressively melts and ‘lays up’ about the interior in the mould after it is warmed up inside an your oven whilst spinning. The form is moved into a chilling station and chilled with air flow and occasionally a thin mist of water once the polymer granules have fully dissolved.

The element hardens because the mould cools down. When the material has cooled enough to discharge through the mould work surface, the process is halted, along with the end result is pulled from the form.Even though the concept of rotational moulding is not difficult, everyone having ever been engaged at the same time will confirm the truth that it must be exceedingly tough.